Unleash enterprise agility with the Pega Platform™

You can’t stop the rate of change – but you can build for it. Learn the ways Pega can help your organization work smarter, unify experiences, and adapt instantly.

Transform your business, one workflow at a time. Pega Platform lets you build, change, and scale up to meet the demands of a rapidly changing world.

Pega Platform empowers your entire organization

Supercharge Pega Platform even further

Unleash rapid transformation with design agents embedded across Pega Blueprint

Give customers 24/7 self-service access to workflows which follow your processes with Conversation agents

Automate end-to-end customer journeys with governed Automation agents

Turn insights into action and give employees info they need anywhere with Knowledge Agents

Increase employee productivity by arming employees with always-on Coach agents

Be nimble, work smarter, scale infinitely.

Drive better business outcomes, faster.

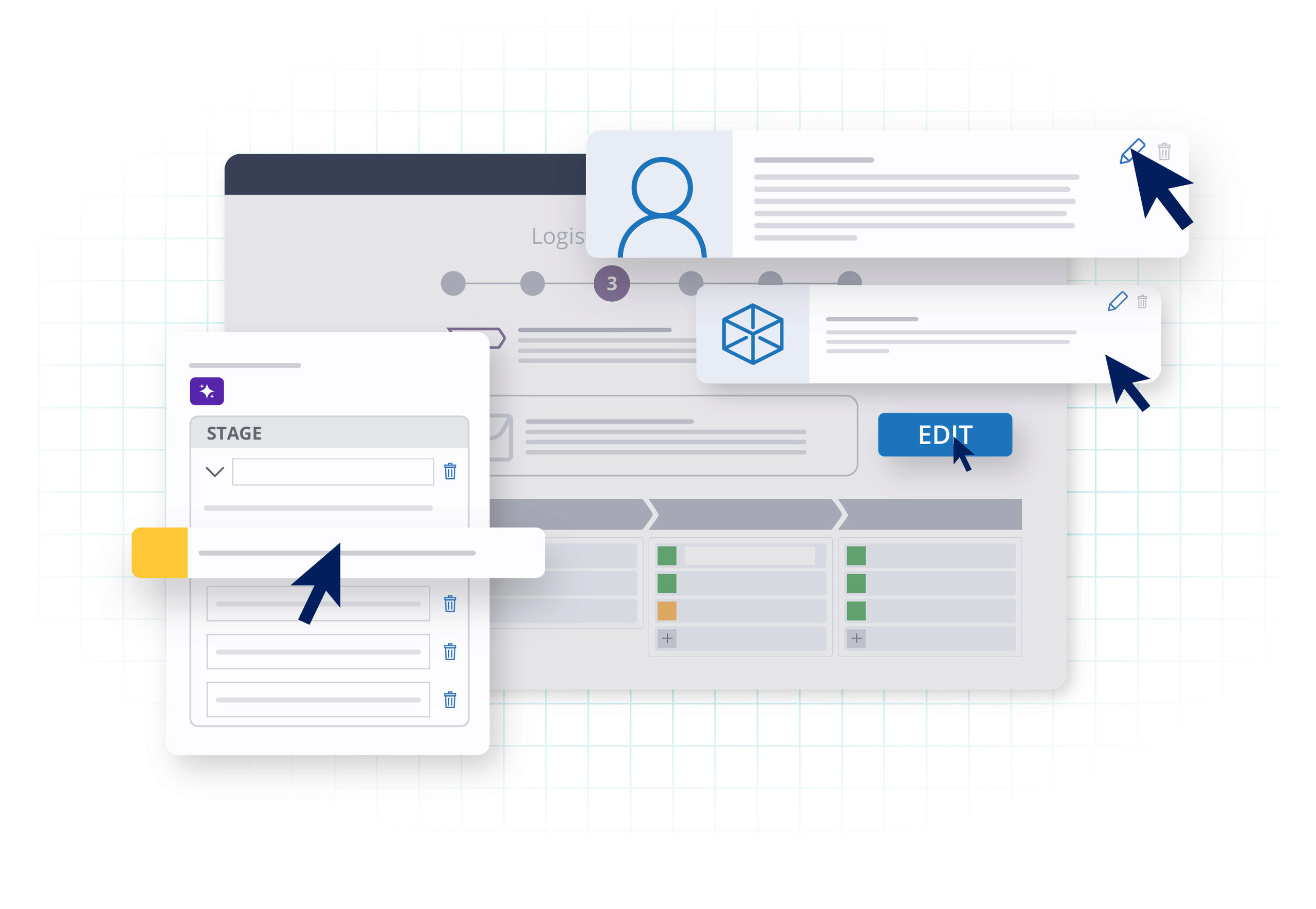

Pega’s powerful business architecture orchestrates work across people and systems – smashing silos and ensuring end-to-end visibility. With your workflows at the center, you can streamline and automate your business processes – for legendary experiences and efficiencies.

Unlock operational excellence.

Automate manual steps by injecting AI-powered decisioning and business logic into your workflows. Identify and mitigate bottlenecks to optimize processes and unlock operational excellence.

Make every employee your best.

Maximize your team’s performance with an intuitive desktop that unifies all their assignments from across your enterprise systems – generating a single, prioritized worklist for each employee. And, with AI-powered assistance, your team can work smarter than ever before.

Adapt. Build. Scale.

Gain agility with a universal framework that drives reuse and enables rapid development with fewer resources. Leave your existing systems and data in place and transform without disruption.

Bring even more power to Pega Platform with these capabilities

Build or buy? Try the best of both.

Choosing between limited, out-of-the-box software or a from-scratch solution is a big decision. But it doesn’t have to be either/or. Pega Platform lets you build the exact applications you want fast with enterprise-grade low code and powerful industry accelerators.

Our enterprise-grade capabilities

Large enterprises have unique needs. That’s why the Pega Platform gives you enterprise-grade capabilities so you can build with confidence, knowing that apps built on Pega will be secure, scalable, governed, and maintainable.