The product lifecycle value chain is fundamentally important to the success of automotive manufacturers and Tier-1 suppliers, but managing its effectiveness and time to market has become notoriously tricky and challenging. Manufacturers are facing an increasing complexity of new technologies and growing ecosystems. At the same time, the need for massive acceleration of time to market lead times and significant improvement of quality and costs targets complicate management of the product lifecycle.

Product lifecycle management – no piece of cake

In part, that’s because complex business operations and product lifecycle activities require companies to juggle many dimensions. On the one hand, they need to balance new features and innovative technologies against cost, risk, and time to market. On the other hand, they need to consider how well they are meeting the needs of customers with varying requirements, increased demand for individualization, and high expectations for outstanding customer service experience – like they experience from companies such as Uber and Amazon. They also need to understand how new products will fit into their existing portfolio and how they stack up against competitors’ offerings.

Automotive companies need to ensure they are making the right use of limited resources, allocating people, time, and money to the projects that will best meet their short- and long-term strategic goals. That raises crucial questions: How should they measure performance, orchestrate their product lifecycle workforce, and manage complex business operations across channels and silos? What is the most effective way to work collaboratively within the growing partner ecosystem and value chain?

A future-proof solution combines process and digitization

Automotive companies need to future proof their business and operating models. They need to be able to transform to shape next-generation operating models that provide the speed, precision, and flexibility necessary to quickly unlock new sources of value and radically reduce costs. The operating model of the future combines digital technologies and process improvement capabilities in an integrated, sequenced way to drastically improve customer journeys and internal processes.

Learn from traditional methods …

Lean management has already played a significant role in putting in place processes, capabilities, and tools to improve how businesses operate. But the digital age has increased both the opportunities for businesses who know how to react and the difficulty of getting it right. For one thing, tasks performed by humans are more complex, whether it’s accessing information in multiple formats from multiple channels and sources or responding to changing market and customer dynamics at ever-increasing speeds. And, as an increasing number of tasks become automated or are taken over by cognitive-intelligence capabilities, companies will need to take many of the lessons learned from lean management and update them.

… add future-proof technology

Digitalization technology is a core element of any next-generation operating model, and it needs to support a much faster and more flexible deployment of products and services. However, companies often have trouble understanding how to implement these new technologies alongside legacy systems, or are slowed-down by outdated systems that move far too slowly.

It all comes down to the DNA of a company – the IT architecture

To address these issues, leaders are building a layer-based modular architecture that supports flexible and reusable technologies. Business process management (BPM) tools and externally facing channels, for example, can be shared across many if not all customer journeys. IT teams collaborate with business teams to assess which systems need to move faster, and use visual models to build business applications in a low-code, model-driven environment 12 times faster than traditional coding. This understanding helps institutions decide how to architect their technology - for example, by identifying which systems should be migrated to the cloud to speed up builds and reduce maintenance.

This approach both accelerates development and prioritizes the use of common components, which in turn leads to development efficiency and consistency. Another important reason for building a more flexible architecture is that it enables businesses to partner with an external ecosystem of suppliers and partners. Similarly, leaders are investing heavily in DevOps and combining people, process, and technology changes to automate software testing, security, and delivery processes, as well as infrastructure changes.

Leverage digitization to achieve acceleration

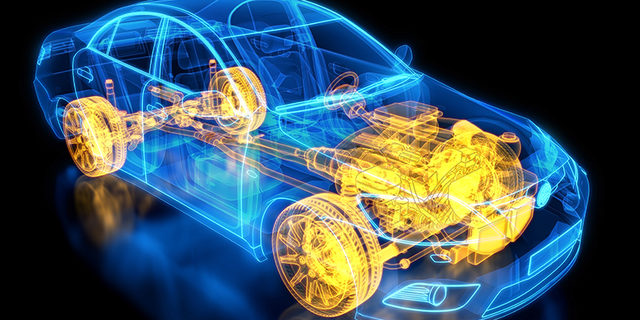

Digitizing the value stream and aligning the digital world with physical devices enables new ways of working across the product life cycle – from design to sourcing, through supply chain, across shop floor, and into the all-important aftermarket. The technologies themselves – social, mobile, big data, analytics, cloud, and of course the Internet of Things – are redefining everyone’s roles and operating models. It’s clear that the fundamental landscape of the industry is being transformed, and that within the next decade, many manufacturers will find themselves managing operations so new and different as to be virtually unrecognizable from the past century of industrial manufacturing.

Enabling this transformation requires enterprise software built with unprecedented levels of ease, utility, and flexibility. Applications must be business-centric, process-oriented, and robustly adaptive to continuous change. They must now include all forms of actors, such as people, systems, and things. And they must support both established and emerging practices, such as Dynamic Case Management, Lean Six Sigma, and Industry 4.0.

Learn More:

- Find out how Pega is helping manufacturing and high-tech organizations accelerate digital transformation.

- Read how top automakers like GM, Ford, Nissan, and Toyota are driving digital transformation.